Explain Different Types of Drilling Machines With Their Specific Features

Ohio Power Tool is a Large Authorized Stocking Dealer Rental and Warranty Service Center. The tang is a flattened portion at the end of the shank that fits into a driving slot of the drill holder on the spindle of the machine.

Drilling Machine Definition Parts Types And Operations With Pdf

A drill press is a machine tool typically used in metalworking industries to perform drilling operations.

. In this machine you will find a vertical column that is attached to the bed that consists of all the gear drives and helps in rotating the knee and saddle. That is why all types of grinding can be done easily with this type of grinders. Peck Drilling frequent retracting of the drill helps to clear chips from the workpiece and prevent drifting.

Unlike other large excavators that run on wheels crawlers run on two large endless tracks and are optimal for mining and heavy-duty construction jobs. There are six types of simple machines the inclined plane the wedge the screw the lever the wheel and axle and the pulley. Ad Sells and rents a full range of foundation drilling equipment.

Its worktable headstock and grinding head are of swivel type. There are two types of drilling machines used by TC 9-524 Reaming counterboring and counter-sinking may require slower speeds than drilling and may not be able to be performed for all materials on these machines. Below are a few special drill bits along with their specific uses.

This is a sort of plain cylindrical grinder. This is a small grinding machine. In addition to the three primary drill types there are a variety of other drills.

Cylindrical Grinders Plain Universal and Centerless grinders Tool and Cutter Grinders. Ad Sandvik Offer Top Productivity Surface Drill Rigs For Any Rock Type. Bar tack sewing machine.

Round column upright drilling machine. Types of Drilling Machine. Vice Jig and fixture.

Other types of drilling machines such as the radial drill press. Milling Fixture for Milling Rough Casting. Maintenance personnel for repairing and fabricating needed parts.

During sharpening it is the body of the drill that is partially ground away. Some of the main types of milling machines are as under. The following points highlight the ten main types of drill jigs.

Floor or bench grinders. Tool and Cutter Grinder. The body of the drill extends from the shank to the point and contains the flutes.

Knee and Column Type. Simple machines unlike complex ones do not work on their own. Circle interpolating also known as orbital drilling is a process for creating holes using machine cutters.

A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. Boring machines come in several variations depending on the size of the work. Internal Grinders Chucking Planetary and Centerless grinders Special Grinding machine.

Upright drilling machine. If using a longer drill for these shallow holes it could have a tendency to drift. Others like the reversible drill fall into one of three main categories of drills but have a feature such as reversibility that.

Horizontal boring mills and jig borers hold the work stationary and rotate the cutting tool. Sensitive drilling machine. Machine Tool for drilling.

Box column upright drilling machine. Upright drill Bench drill Radial drill Gang drill - 2-6 drills together NC drill. Also known as compact excavators these excavators use hydraulic power mechanisms to.

Spotting Drills short drills used to create shallow or pilot holes. Following are the 8 different types of drilling machine. These six have specific features and do unique jobs even though some may work in similar ways.

The most common type of milling machine is called knee and column. It is used for binding cut edges and to sew flat seams on knitted fabrics. It can be either hand-powered or electrically powered and often includes a work surface called the bed which allows the piece being drilled to be held vertically.

The cutting tool can then be moved simultaneously in an axial direction to drill or machine a hole andor combined with. Some like the brace are highly specialized. Drill reamer tap and the particularly milling cutter are grinded with this grinding machine.

Angle-Plate Jigs and Fixtures 5. There are two types- one with a flat bed and one with a cylindrical bed. Ad Drilling Equipment Made with the Technology You Need to Make Your Projects Successful.

Milling machines are available in many types. Ad Hougen - HMD130 - HMD904 - HMD918 - HMD505 - Magnetic Drill Options Annular Bits. Floor column upright drilling machine.

A vertical boring mill is used to machine very large heavy castings where the work turns while the boring bar is held stationary. Orbital drilling is based on rotating a cutting tool around its own axis and simultaneously about a centre axis which is off-set from the axis of the cutting tool. This type of machine only makes bar tacks the stitching which reinforces specific areas of garments and accessories like on top of pockets belt loops.

Some simple machines may be a combination of simple machines. Vise-Jaw Jigs and Fixtures 7. Bench mounting sensitive drilling machine.

Different Types Of Drilling Machine Operation Studentlesson

Mechanical Engineering Drilling Machine

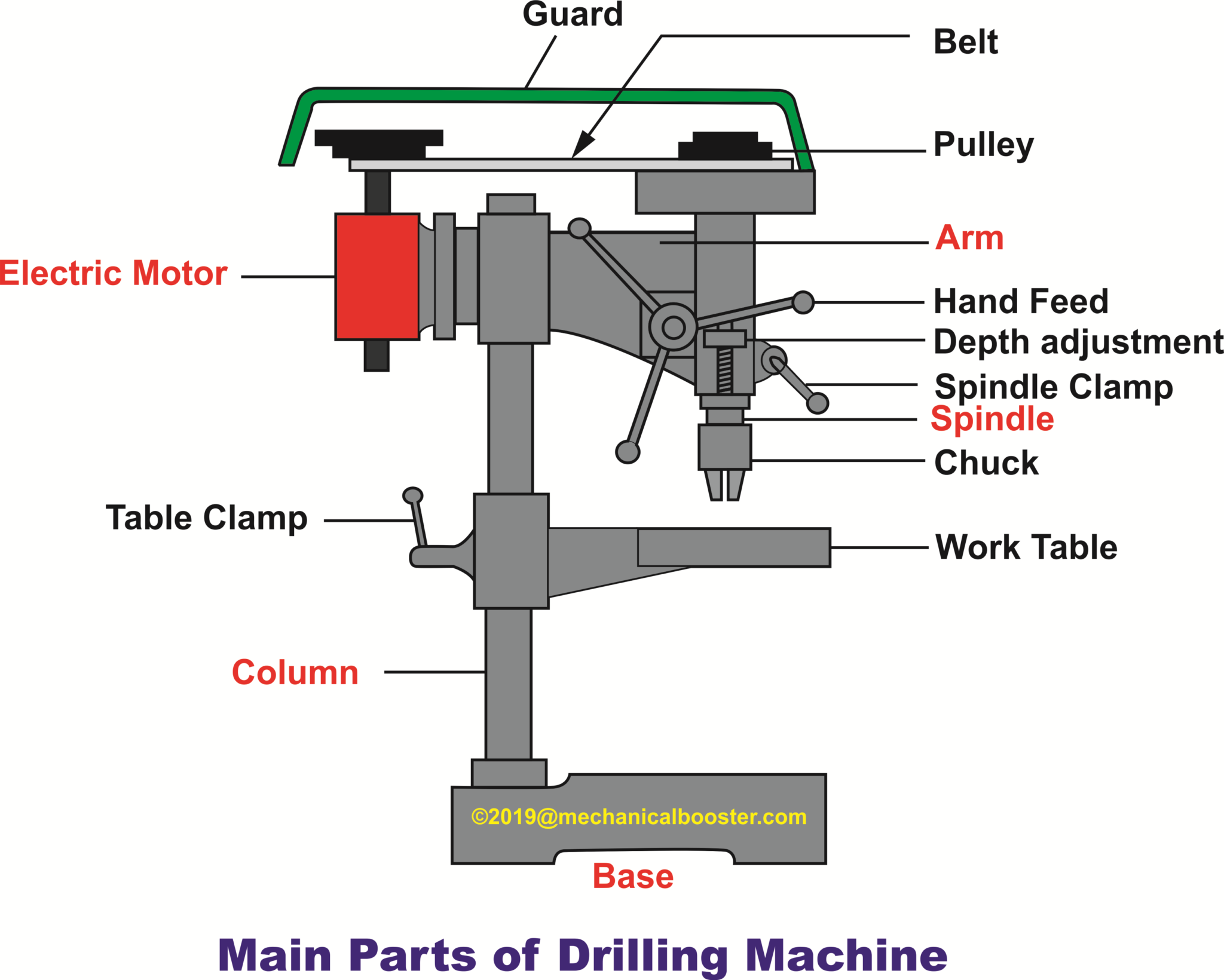

What Is Drilling Machine And How It Works Mechanical Booster

No comments for "Explain Different Types of Drilling Machines With Their Specific Features"

Post a Comment